Ball valves are frequently used in many fields. These valves continue to see increased interest and use. Have you ever pondered the significance of ball valves in various contexts? In this post, you’ll go through the typical parts of a ball valve and what they do. In addition, you will read about the operation of a ball valve to familiarise yourself with it before you purchase it for your use.

What Is a Ball Valve?

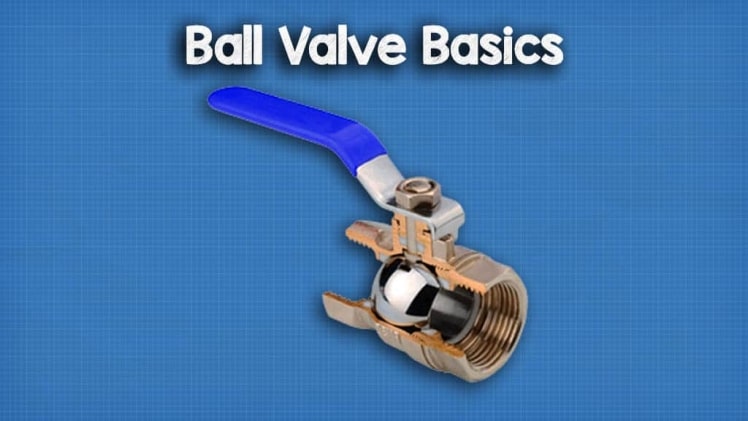

When closed, the ball valve’s disc, which is shaped like a ball, works as a seal. Ball valves are often designed as quarter-turn valves. However, other types are possible when used to regulate or redirect the flow of media.

These valves are frequently utilised where reliable sealing is essential. It is common knowledge that they experience sudden reductions in pressure. Even when dealing with high volume, pressure, or temperature material, the 90° turn makes it simple to use. Because of their durability and longevity, they are cost-effective.

These valves work best with clean, particle-free gases or liquids. These valves are not recommended for use with slurries due to the vulnerability of the soft elastomeric seats to damage. They can be used as throttles, although they aren’t typically used for that purpose since the seats wear out quickly under the stress of throttling.

Benefits of These Valves

- The ball valve is straightforward in its construction.

- Compared to a gate valve, this one can only handle a fraction of the flow and is far more portable.

- It can be taken apart and fixed quickly.

- The packing seal on the stem of this valve is robust and difficult to break.

- This valve design allows for little fluid resistance. Pneumatic valves have one of the lowest fluid resistances of any valve design.

- It has an efficient cycle time and is user-friendly.

- It has a low-pressure drop and a high flow rate.

- The seal is as good as it gets.

- Speedy opening and closing.

Components

These valves consist of many essential components:

Valve Body

The valve’s major portion contains all the on/off control components.

Rotating Ball

The ball is built with a central bore (hole) through which the fluid flows—turning the stem controls the ball’s direction.

Seats

These discs are situated between the body and the ball. In addition to providing a seal between the two, seats support the ball.

Energy Source

The stem of the ball valve is turned using either manual or electrically-powered mechanisms. Manual actuation consists of levers and handles under the direction of an operator. Available automated power sources include electric, pneumatic, and hydraulic actuation.

Packaging

This stem closure prevents media from escaping.

Bonnet

The bonnet is the body component that houses the stem and packing.

Ball Designs

Manufacturers can make balls in two main layouts: a floating design or a trunnion design. Costs for trunnion balls tend to be higher than those for free-floating alternatives. The floating balls are supported by cupped seats, creating a snug fit between the user and the ball. Trunnion balls are similar to floating balls in terms of their intended use. However, they differ because their seats are spring-loaded, and the ball can only spin in a single plane. Working torque is reduced for trunnion valves.

Ball valves are the most common type of valve used in plumbing systems and related fields like industrial cooling. In most cases, they regulate the quantity of fluid or gas passing through a particular opening, influencing the pressure distribution in the rest of the system.